A human detects objects with his or her eyes. A vision inspection system detects objects with digital cameras before processing the information with an image processing software.

A human detects objects with his or her eyes. A vision inspection system detects objects with digital cameras before processing the information with an image processing software.

Many industries depend on machine vision to not only detect objects but to ensure products sent to customers are undamaged and of the highest quality.

Continue reading to learn how a vision inspection system detects objects.

What is Machine Vision?

Machine vision gives a the ability to “see” like a human. Machine vision depends on four critical elements to be successful: Lighting, staging, lenses, and cameras.

Lighting

In order for your vision inspection system to work as intended, you’ll need to make sure you have proper lighting in your facility. This is why it’s important you make sure the overhead lights in your factory are always properly lit. Even one burned-out bulb could be enough to affect the performance of your vision inspection system.

Staging

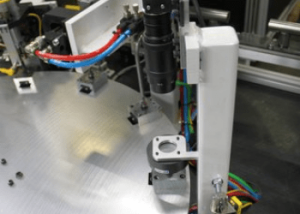

Staging is how items are held in place and positioned in front of the camera so the vision inspection system can take a clear image. If you need to inspect several sides, the item may be rotated so more surfaces are inspected.

Lenses and Cameras

A camera lens is a curved piece of glass that bends light. The lens gathers the light reflected or transmitted from the object you want to inspect before it travels to the sensor. The sensor then changes the light into electrical signals and digitizes them into what are called pixels. Once the image is captured, it’s processed by the vision inspection system.

Machine Vision vs. Computer Vision

So, what’s the difference between machine vision and computer vision? While both of these technologies overlap in how they’re used, you can’t have machine vision without computer vision. This is because machine vision is an offshoot of the broader category of computer vision.

In general, machine vision refers to the use of computer vision for industrial automatic systems. Depending on your facility, you may be using machine vision for things like guiding industrial robots or inspecting products. Companies often use machine vision to perform a specific function, which is why we recommend giving us a call. As a custom machine builder, we’ll be able to help you clearly define the goals you want to reach with a .

Machine Vision vs. Humans

A human worker’s performance tends to fall over time with tedious tasks. Yet, a vision inspection system can run 24/7 and maintain a high level of accuracy. Also, human inspectors are more likely to miss anomalies that don’t fit neatly into the categories they’re trained to look for. These issues worsen as the throughput increases.

For the above reasons, most industries are able to justify using machine vision to improve quality management. Using machine vision will help your company put out products of consistently high quality. To learn how to integrate a vision inspection system into your existing automation, give us a call. We’ll be more than happy to help you find an innovative solution.

Call Paramount Tool Company

We take pride in building quality machines and automation systems, but it’s our process that really makes the difference! We work with you one-on-one, providing personalized service from beginning to end.

Paramount Tool Company is a custom machine builder in Holland, MI that has served customers since 1967. Our legacy of providing smart manufacturing solutions has lasted over 50 years and will continue into the future. To request an estimate for a vision inspection system, call (616) 582-5300.

(616) 582-5300

(616) 582-5300